N'ebe a na-emepụta semiconductor nke ukwuu, ọbụlagodi obere ịma jijiji nwere ike imetụta arụmọrụ nke igwe slotting wafer, na-eduga na ntụpọ na mfu. Ntọala igwe Granite apụtala dị ka egwuregwu - ngwọta na-agbanwe agbanwe, na-enye ịma jijiji na-enweghị atụ - ikike mbelata dị oke mkpa maka idobe iguzosi ike n'ezi ihe nke nhazi wafer.

Njupụta dị elu na inertia maka mbelata ịma jijiji

Njupụta dị elu nke Granite, na-adịkarị site na 2,600 ruo 3,100 kg/m³, na-enye nnukwu inertia. Mgbe etinyere n'ime igwe slotting wafer, njirimara a na-eguzogide mmaji mpụga nke ọma. Dịka ọmụmaatụ, n'ala ụlọ mmepụta ihe semiconductor na-arụsi ọrụ ike, igwe ndị gbara ya gburugburu na okporo ụzọ ụkwụ nwere ike ịkpalite ịma jijiji gburugburu. Igwe igwe granite, nke nwere oke ya dị arọ, na-arụ ọrụ dị ka ntọala kwụsiri ike, na-ebelata nnyefe nke ịma jijiji ndị a na akụkụ ndị siri ike nke igwe slotting. N'ihi ya, ngwaọrụ ịkpụchasị ahụ na-edobe ya nke ọma, na-ebelata ihe ize ndụ nke nkwụsị - mbelata ihe mgbaru ọsọ na imeziwanye ogo nke wafers slotted.

Mmaji eke eke - Njirimara na-emebi emebi

Ọdịdị dị n'ime ụlọ pụrụ iche nke granite, nke mejupụtara mkpụrụ osisi mineral na-ejikọta ọnụ, na-enye ya ọmarịcha ịma jijiji - ike damping. Mgbe igwe slotting wafer na-arụ ọrụ, ntụgharị ọsọ dị elu nke ngwaọrụ ịcha ihe na ihe ndị na-arụ ọrụ na-arụ ọrụ nwere ike ime ka mma ahụ dị n'ime. Granite na-amịkọrọ ma na-achụsasị ike a na-ama jijiji, na-egbochi ya ịmalitegharị site na nhazi igwe. N'adịghị ka ntọala igwe nwere ike ịkwalite ịma jijiji, mmetụta granite sitere n'okike na-eme ka a hụ na igwe na-arụ ọrụ nke ọma. Nnyocha na-egosi na iji ntọala granite nwere ike ibelata njupụta vibration site na 70%, na-eme ka igwe slotting nwee ike ịnọgide na-enwe ọkwa dị elu nke ziri ezi n'oge usoro ịkpụ.

Nkwụsi ike ọkụ iji gbochie ịma jijiji - Njehie ebutere

Mgbanwe okpomọkụ na gburugburu ebe a na-emepụta ihe nwere ike ime ka ihe gbasaa ma ọ bụ nkwekọrịta, na-eduga n'adịghị mma na ịma jijiji na-esote. Granite nwere ọnụọgụ dị ala nke mgbasawanye ọkụ, nke pụtara na ọ na-edobe udi ya na akụkụ ya ọbụlagodi n'okpuru ọnọdụ okpomọkụ dị iche iche. N'ime igwe slotting wafer, nkwụsi ike nke okpomọkụ a dị oke mkpa. Dịka ọmụmaatụ, n'oge a na-arụ ọrụ mmepụta ihe, igwe nwere ike ikpo ọkụ n'ihi ọrụ na-aga n'ihu. Ntọala granite na-achọpụta na akụrụngwa igwe ahụ na-anọgide na nhazi nke ọma, na-ezere mkpagharị ọkụ ọ bụla na-akpata ma ọ bụ mgbanwe akụkụ nke nwere ike imetụta izi ezi nke oghere wafer. Nkwụsi ike a na-enyere aka hụ na ịdị mma na-agbanwe agbanwe n'ofe wafer niile edoziri.

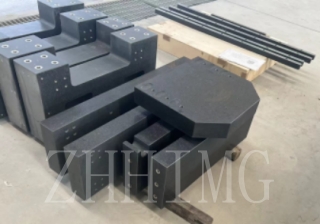

Rigid and Stable Foundation for Precision

Nkwụsi ike nke granite bụ isi ihe ọzọ na-ebelata mkpọtụ. Nhazi ya siri ike na-enye ntọala kwụsiri ike maka igwe oghere wafer, na-egbochi mmegharị ọ bụla na-achọghị ma ọ bụ mgbanwe. Izi ezi - ala ala nke isi igwe granite na-enyekwa ohere maka ntinye ziri ezi nke akụrụngwa igwe, na-eme ka nkwụsi ike dịkwuo elu. Mgbe igwe kwụsiri ike na ntọala granite, ọ nwere ike ịrụ ọrụ na oke ọsọ yana obere ịma jijiji, na-eme ka oge nhazi ngwa ngwa n'achụghị nkenke.

Ezigbo - Akụkọ ịga nke ọma n'ụwa

N'ime ụlọ nrụpụta semiconductor na-eduga, nnabata nke ntọala igwe granite na igwe wafer slotting butere mmụba dị ịrịba ama na ogo mmepụta. Mgbaji ahụ - Njirimara mbelata nke granite belatara ihe omume micro - fractures na wafers slotted, na-abawanye ọnụego mkpụrụ sitere na 85% ruo 93%. Na mgbakwunye, nkwụsi ike emelitere nyere ohere mmụba 20% n'ọsọ arụ ọrụ nke igwe, na-akwalite nrụpụta n'ozuzu ya.

Na mmechi, ntọala igwe granite na-arụ ọrụ dị mkpa n'ibelata ịma jijiji na igwe slotting wafer. Njupụta ha dị elu, ịma jijiji - ihe ndị na-akụda mmiri, nkwụsi ike ọkụ, na nkwụsi ike na-ejikọta iji mepụta ebe kwụsiri ike na nke ziri ezi. Maka ndị na-emepụta semiconductor na-achọ imeziwanye ogo na arụmọrụ nke nhazi wafer ha, itinye ego na ntọala igwe granite bụ ihe a nwapụtara ma dị irè.

Oge nzipu: Jun-12-2025